WhatsApp)

WhatsApp)

Cement finish milling; cement finish mill water rate Cement Grinding with Roller Press Technology –. Certainly compared to ball mills and VRMs ...

Concrete Pouring Finishing for Jobs of All Sizes. Carolina''s Concrete Finishers serves Richburg, Rock Hill, Fort Mill, Lancaster, Indian Land, Chester, Charlotte ...

Cement Finish Mill Application. Pyroprocessing or Drying Application. ... it was faced with the limitations of a manual approach to optimizing its finishing circuit.

Cement grinding Vertical roller mills versus ball ... to a cement mill is often completely dry ... conditions associated with finish grinding of cement clinker and ...

cement temperature control in finished mill BINQ Mining. cement finish mill temperature control – Grinding Mill China. Cement mill – Wikipedia, the free ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

Cement Process Chemistry Presentation Transcript. About Cement . Cement Chemistry ; Cement is hydraulic material which develops strength when it .

Feb 25, 2008, closed conveying systems; clinker and cement silos; coal mill; finish mill, spraying quench water or a slurried reagent (such as slaked lime or.

Jun 02, 2013· Drying Capacities for Raw Material Explanation – The Cement . The Cement Grinding Office . like raw mill, coal mill or cement mill. .. An other ...

finish mill cement. wet grinding and dry grinding; both open circuit grinding and closed circuit grinding For ores and minerals grinding, there are ball mill ...

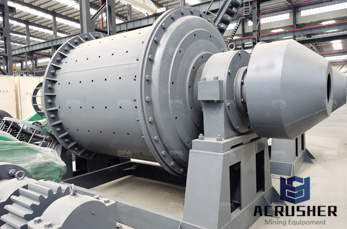

Ball mill Grinding ThyssenKrupp Industrial Solutions. The proven classical option for cement grinding Whether employed as a twocompartment separator mill in an ...

cement finish grinding and distribution – Crusher South Africa. vertical roller mill flow chart india Tin Can Processing Plant Flow Chart; Ball Mill Made in India; .

Portland Cement MACT Training 7 raw mill storage silos 8 flame end incoming raw meal kiln clinker cooler raw meal enters kiln flame end of kiln 9 finish mill

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Cement mill Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from ...

finish cement grinding with vertical roller mills. cement vertical finish mill mineral coal mining in india. Product 20 30 Vertical roller mills are large grinding ...

CEMTEC manages every project from start to finish. ... cement mills can also be confi gured with a drying chamber. ... the cement mill can

tph cement finish mill price. tpd Cement Plant for Sale by Nelson Machinery Internationalvertical roller mill or roll press circuit in finish grinding mode for ...

Ball mills, that are commonly used for finish grinding, have high energy demands, consuming up to 3042 kWh/t clinker depending on the fineness of the cement.

section 033053 miscellaneous castinplace concrete, C ACI 318 Building Code Requirements for Reinforced Concrete, Cement remaining in bulk storage at the mill ...

offers 2,048 finish mill cement products. About 1% of these are cement making machinery. A wide variety of finish mill cement options are available to you ...

cement finish mill water rate loratradexin. Cement Grinding with Roller Press Technology –, Certainly compared to ball mills and VRMs, this is costeffectivedue ...

Cement mill Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from ...

WhatsApp)

WhatsApp)