WhatsApp)

WhatsApp)

Pipemill: a suite of piping design analysis programs ... pipe flange design and analysis ... PSV and Rupture Disc force calculation;

Strip Widths for Welded Tubes How Breakdown and Fin ... RollKraft Each fin pass applies force to the strip edges of the tube to not only force the outside ...

tube mill design calculation force roll Tube Mill Roll ... A large suite of software has been developed for the calculation of optimised rolling schedul The ...

Rolling of metals •Introduction ... understanding of load calculation in rolling processes. ... Cantilever mill roll Tube mill roll Universal roll Ring rolls

A determination of the total roll separating force during rolling of ... During the technology design the rolling separating force is a ... sults of calculation by ...

Home>Crusher and Mill >tube mill design calculation force roll. tube mill design calculation force roll. Tube Mill Roll Design: data M COPRA® RF ...

The Calculation of R... | Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic ...

Tube Calculator . Definitions . Safety ... what these numbers actually mean and why we should consider them during roll cage design. ... provided by Rogue Fabrication

Tube and Pipe Roll Tooling Design. If you want to produce the best and most cost effective tube and pipe, you need the best tooling design. Most tube and pipe ...

Fenn manufactures a complete line of precision engineered metal Rolling Mills as well ... force capacities ... rolling expertise and design flexibility we ...

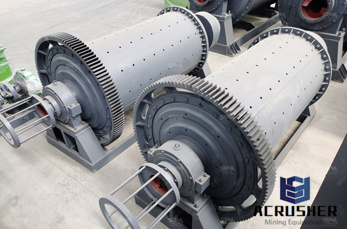

Ball and tube mills A ... center or side of the pulverizer (depending on the design). ... as an applied force mill. There are three grinding roller wheel ...

Rolling mill roll design ... Cook and McCrum''s Method of Calculation of Roll Separation Force 26 ... Setting up the Matrix for Section Rolling Roll Design

Accurate and Rapid New Model for Mill Deflection and Strip Thickness Profile ... in rolling mill design, ... Plane strain problem of determining rolling force ...

Need bending calculations? Visit our website today to get all the tools you need to calculate arc length and the radius of a bend.

Calculates the rolled length of a roll of material when the outside diameter of the material, thickness of the material, and the diameter of the hole in the center or ...

how to calculate tube mill roll design Patent US Calibration of an instrument for the coldrolling . Mar 26, 2002 Tool design for tube cold pilgering, in ...

Further information on machine design ... Force on each belt strand F N ... Calculation constants c.. – Drum/roller diameter d mm

The highprecision tube roller mill process is a fast, ... and roller design to reduce tube crosssection up to 90 percent. ... Calculation for tube reduction ...

Jan 31, 2009· Sorry for being late getting back, yes the bend formula works for rolling as well, ... White Paper: Collaborating in SOLIDWORKS to Design a “Supertruck ...

Steel Tube and Pipe ... it was reborn as one of the most efficient tube rolling mills ever ... rolling mill facilities of comparatively disparate design were ...

Free Mechanical Design, Engineering Calculators Online engineering ... Three Gears or Pulleys Force Calculations and ... Pipe Shell Design Calculator Pressure ...

The basics of roll form tooling design Understanding tube ... which can limit roll design options. Calculate the ... with the rolling mill. During the design ...

Tube Pipe Mill Machinery. Roll ... Roll Shaft. Do you need a source ... We want to redesign and improve on your current shaft design. Precision engineered mill roll ...

Complexity of pilgering in nuclear applications ... Vertical Mass Ring die mill, Cold Rolling Tube Mill Introduction ... This allows for precise calculation of wall

WhatsApp)

WhatsApp)