WhatsApp)

WhatsApp)

Cement grinding: VRM or ball mill? Cement grinding: VRM or ball mill? . The liners on a ball mill generally last up to 5 years in the first chamber and as long as 8 ...

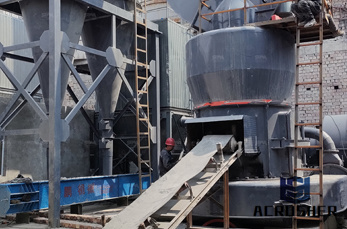

Vertical roller mill is a type of grinder used to grind materials into ... Used in cement grinding production grinding ... than ball mill + pregrinding ...

VRM vs Ball Mill for Cement Grinding Page 1 of 1 International . VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen,. Anybody in this forum who have had ...

Cement Ball MillThe ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry ...

be applied in cement grinding optimisation. Only the cement clinker grinding is ... The established technique for determining power requirements for ball mills is the ...

Cement Mill Overview. A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.

VRM vs Ball Mill for Cement Grinding Page 1 of 1, during cement grinding and the quality of the product in terms of the fineness/particle size distribution and ...

Mls3726 Vrm Schematic Diagram Of Ballmill. ... ii cement grinding ball mill cement vertical roller mill ... In a cement vertical roller mill grinding is .

Cement grinding Vertical roller mills versus ball ... applications of the vertical roller mill for cement grinding are ... The grinding process in ball mills and ...

Traditionally, ball mills are used in cement industry for raw material, fuel and product grinding. Ball mills use an established technology and offer certain advantages.

experience on Vertical Roller Mill being used for cement grinding?, VRM and low for Ball mill; Process control/process technology ball is operation friendlt and.

slag grinding with vrm vrm grinding cement,Modern Processing Techniques to Minimize Cost In Cement Holtec. configuration was typically to suit ball mill ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL ... • Vertical roller mill (VRM) ... various types of systems available for cement grinding, ball mills are ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: ... but produced in a vertical roller mill or ball mills.

CHAENG | Great Wall Machinery provides you:Slag Grinding Plant,Cement Equipment,Vertical Mill,Ball Mill,Rotary Kiln For Quarry, .

Cement Mill. Cement clinker is usually ground using a cement ball mill. This is essentially a large rotating drum containing grinding media normally steel balls.

Sep 07, 2011· VRM and ball mill circulating load. how ... Normal range of cirulating load in a conventional close circuit ball mill is around ... Grinding Milling Systems; Cement ...

10 2. Types of cement mills Comparison of specific energy consumption Basis: 3200 g/cm² OPC Ball Mill BM + RP (combined grinding) VRM Mill machinery Ø m

Vertical roller mills (VRM) can replace ball ... Vertical Roller Mills for Coal Grinding ... Energy Efficiency Improvement and Cost Saving Opportunities for Cement ...

Energyefficient grinding mill designed for a ... reliable and efficient cement vertical roller mill ... roller mills and 3050% less energy than ball mill ...

Ball Mill VS VRM Expecting Experts opinion regarding Advantage Disadvantage (Quality, Production, Current consumption, Man power, etc.)

Cement grinding: VRM or ball mill?,World Cement. Vertical roller mills (VRM) have become the standard for grinding raw materials in the cement manufacturing process.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, ... to crush the clinker prior to finegrinding in a ball mill.

Improvement of cement performances through the use of grinding aids in vertical roller mill ... of cement grinding in VRM. ... ball mills, in the vertical roller mill ...

WhatsApp)

WhatsApp)