WhatsApp)

WhatsApp)

Grain sorghum flours and grits will be evaluated for wet milling quality with an established benchscale procedure starting with 100g of material.

Traditionally, ethanol from corn has primarily been produced through dry and wetmilling processes. The majority of ethanol production is from drygrind technology.

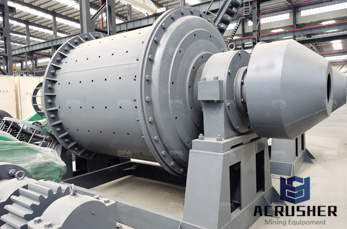

Ball mill, Ball millingcutter All industrial, ball mill / horizontal / for the pharmaceutical industry / wet 90 M HOSOKAWA, Dry grinding as low as below 5µm ...

Table of ContentsBatch Ball Mill GrindingWet and Dry Open Circuit Ball MillingType of Grind with Different Amounts of Ore Charges in Wet and Dry Ball Milling Batch ...

Wet Milling or Dry Milling? Learn the differences, materials best for each type of milling and how to determine your return on investment.

Dry milling and fractionation of grain This article has multiple ... "Review of New Information on the Use of Wet and Dry Milling Feed byProducts in Feedlot ...

Wet milling: Wet milling with IKA''s inline machines is a safe and efficient alternative to dry grinding. Dry grinding creates a lot of dust which causes the need for ...

Dry Mill PilotinaIKA® Pilotina MUThe universal 2 in 1 mill for dry products. The IKA® Pilotina MU is the optimal solution for most milling applications.

Proto3000 offers you a collection of dental milling machines with the option to perform wet and dry milling. Create powerful results with our highly precise dental ...

How Ethanol is Made? ... Roughly 90% of the grain ethanol produced today comes from the dry milling process, ... Wet Mill Ethanol Process.

Wet And Dry Mill, Wet And Dry Mill Suppliers and . Wet And Dry Mill, Wholesale Various High Quality Wet And Dry Mill Products from Global Wet And Dry Mill .

Leading expertise in dry grinding and wet milling applications in the pharmaceutical, food, chemical and personal care cosmetics industries.

The Ethanol Production Process Wet Milling. While the basic steps remain the same, the process has been considerably refined in recent years, leading to a very ...

The choice between wet and dry milling is, in general, unimportant in smallscale milling but is a major technical problem when largescale milling in the ...

Dry Milling is the most common ethanol production method in the United States; it also the least intensive method for producing ethanol.

The Benefits of WetMilling APIs. Posted: ... Unlike traditional dry milling techniques, wet mills do not lead to the release of dust into the production facility.

Chris Frye of Whip Mix takes a look at the differences between wet milling and dry milling.

Dry and Wet Milling Two different approaches in grain processing. As only the starch is needed as a carbohydrate source for the biological conversion process, the ...

Rice flour from nine varieties, subjected to dry and wetmilling processes, was determined for its physical and chemical properties. The results revealed that ...

Roland DGA recently announced the release of the DWX4W, our company''s first wetmilling machine. It was added to the Roland family of dental milling devices in ...

wet milling vs dry milling. difference between dry milling vs wet milling gold ore wet milling vs dry milling,wet milling and dry milling Grinding Mill China wet ...

Wetmilling is a process in which feed material is steeped in water, with or without sulfur dioxide, to soften the seed kernel in order to help separate the kernel ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction needs.

Corn Milling, Processing and Generation of Coproducts Corn, ... There are two distinct processes for processing corn, wetmilling and drymilling

WhatsApp)

WhatsApp)