WhatsApp)

WhatsApp)

in cement mill how to control residue – Grinding Mill China . Gulin Least News Optimizing manganese ore sinter plants: process parameters and design implications ...

Reducing the SO2 emission from a cement kiln. ... The aim of our study is to reduce the SO2 emission without affecting the quality of the end product.

Permit Summary – Addition of a Kiln and Related Operations . ... a coal/pet coke mill, a finish mill, and cement ... mills in combination with a ball mill to reduce ...

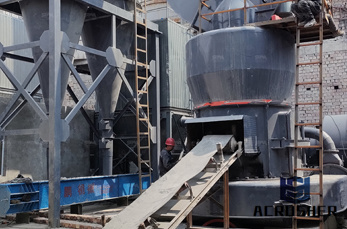

cement vertical mill grind materials to related fineness by grinding rollers, Cement Vertical Roller Mill,Vertical ... can reduce the delivery period of ...

grinding the resulting clinker to make cement (see Cement mill). ... The cement kiln system is designed to ... coal and use of alternative fuels can reduce net ...

New Concrete Production Craft Slag Instead of Cement. ... Added slag powder can reduce cement using ... In Commercial Concrete Production Big Grinding Mill ...

Cement mill Wikipedia, the free encyclopedia. A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into ...

Reducing energy consumption of a raw mill in. In a cement plant, using energy efficiently during grinding process will lower the production costs considerably.

Efforts to reduce energy demands, by ... ABB in cement Raw mill Quarry Coal mill Cement mill Packing and distribution Cement silos Filter Filter Additives Limestone/Clay

CHAENG cement ball mill equipment can reduce energy consumption by 30% and increase the processing amount by 1520% after transformation.

cement plant to reduce preheater tower . ... Estimates suggest that the Spanish cement industry could reduce its specific direct ... ball mill steel balls for sale;

how to reduce energy in the cement mill small ball mill, how to reduce energy in the cement mill | Solution, Coal dosing to cement kilns and PFA dosing to cement ...

Modern Processing Techniques to minimize cost in ... cement and minerals, whereas Cemax Mill is mainly ... possible to reduce the heat consumption to .

cement mill ball mill tube ... Cement Grinding Aid. ... The grinding plant at a cement factory is used to reduce the particle size distribution of various ...

Cement mill Residue. Sir, We have a ball mill for cement grinding. The residue on 45 mic is 15 to 16 % for blains value of 3400 cm²/grms, any idea how to reduce the ...

However, cement producers can significantly reduce motor energy usage by implementing intelligent motor control solutions, ... coal mill exhaust fan, ...

Cement mill including cement ball mills and cement vertical mills . Cement mill includes cement ball mills and cement vertical mills. . we can realize the role of ...

Cement Crusher To Reduce The Power. Granite Crushing Plant. After first crushing, the material will be fed into cone crusher by belt conveyor for secondary crushing;

cone gear reducer, gear reducers,, plant,mechanical reducer cement mill ... Cement Mill Packing Plant Supervisor job which can reduce... » Learn More.

Cement manufacturing machine for cement plant ... Cement crusher machine is used which help reduce the large solid chunks into ... > Ball mill used in cement .

Precalciner Cement Kiln Mercury (Hg) Emissions Control by ... With the raw mill operating there is ... control strategy for any cement plant wishing to reduce ...

ABB drives in cement ... cement producers need to: − Reduce energy consumption per ton of produced cement ... Raw mill and separation − Fans

The lumps in the cement. ... gypsum dehydration in the cement storage silo. Have cement mill ... measures will reduce lump formation in cement ...

After the grinding process in a cement mill, ... forces on the bearing unit of the mill and heat loss from the pipes and mill mantle. In order to reduce losses, ...

WhatsApp)

WhatsApp)