WhatsApp)

WhatsApp)

The wet mill of a corn plant refers to area where the corn is separated into its individual components of starch, gluten, fiber, and germ. The separations in the wet ...

Wetmilling is a process in which feed material is steeped in water, ... wetmilling plants can separate a 56pound bushel of corn into more than 31 pounds of ...

REVIEW MILLING Wet Milling of CornA Review of LaboratoryScale and Pilot PlantScale Procedures N. SINGH'',2 and S. R. ECKHOFF1 .

The corn wetmilling industry has established the process of breaking corn into its component parts, corn oil, ... enzymes and minerals for the plant to grow.

Corn wet milling and dry milling are the predominant methods of processing corn and each method produces distinct coproducts. Read more here.

Corn Milling, Processing and Generation of Coproducts ... The Corn WetMilling Process Wetmilling processing roots are designed based in production of pure starch.

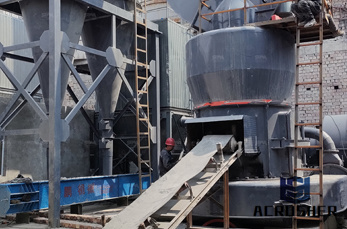

Equipment and Systems for Corn Wet Milling. Corn Wet Milling Process Flowsheet 2. 3 Dewatering, Germ Washing, ... Varying plant capacities can be handled.

Engineering process and cost model for a conventional corn. Engineering process and cost model for a conventional corn wet milling and the sale of wet corn became the ...

Golden Growers Cooperative ... and ProGold owns a corn wetmilling plant near Wpeton, North Dakota. The ProGold plant makes high fructose corn sweeteners, ...

Corn Wet Milling Plant, Wholesale Various High Quality Corn Wet Milling Plant Products from Global Corn Wet Milling Plant Suppliers and Corn Wet Milling Plant .

Chemineer agitators and Kenics static mixers are utilized throughout the corn wet milling process.

During wet milling, corn ... some solubles, but this can vary from plant to dry milling ethanol process (Figure 2) is relatively simple where corn ...

Conventional wet milling of corn is a process designed for the recovery and purification of starch and several coproducts (germ, gluten, fiber and steep liquor).

Cargill to close Memphis corn milling facility. ... facility results primarily from the underutilization of the Memphis plant and its location away from the corn belt.

The corn wetmilling is a process of breaking corn kernels into their component parts: corn oil, protein, corn starch, and fiber. It uses water and a series of steps ...

How Ethanol is Made? ... Take a virtual tour of an ethanol plant and learn about the production process. ... Wet Mill Ethanol Process. In wet milling, ...

Emission Factor Documentation for AP42 Section Corn Wet Milling ... Shelled corn is delivered to the wet milling plant primarily by rail and truck and

Corn Milling Process. ... separating fines and broken from the whole corn. Occasionally wet cleaning follows to remove surface dirt, dust and other matter.

Yellow Dent Corn Grain iature plant made up of a root like portion and five or six embryonic leaves. In addition, ... The Corn Wet Milling Process Fermentation

ANDRITZ is a knowledgeable, experienced partner in the production of ethanol through corn wet milling. Our equipment deliver reliable and high output.

Incorporated in 1943, GPC was formed as an alcohol plant and has since grown to include maltodextrins, corn coproducts and a corn wet milling plant

Baking industry news and commentary offering insight on business, new products, regulatory, market and product trends, supplier innovations and more.

The corn plant is a tall annual grass with a stout, ... Corn grain is processed by wet milling, ... corn Children''s Encyclopedia ...

Wet Milling of Cereal Grains ... Wet milling, sorghumwhich has ... shipped out as crude corn oil or is re fined in the plant.

WhatsApp)

WhatsApp)