WhatsApp)

WhatsApp)

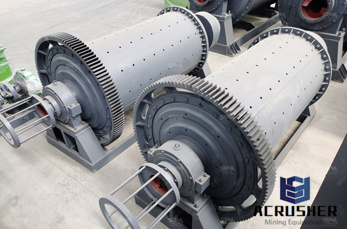

This series of ball mill is suitable for ore dressing, chemical, coal, cement and refractory sectors to operate fine grinding. Bearingtype drive ball mill is a ...

The air from the cement mill will be dedusted in a bag filter before being vented out to the ... The packing plant is planned to operate 24 hours a day through three ...

how to operate vertical mills in cement plant. Stone . Our company is a manufacturer and exporter of the crushers, serving the crushing aggregate industry for 20 ...

Operation Of Weigh Feeder In Raw Mill. ... for dosing raw coal and petcoke to the coal mill. CaSe: Cement ... operate with an inline raw mill and preheater ...

Vertical cement mill in operation. Cement Manufacturing | Vertical Roller Mills for Finish Grinding . Almost all ball mills use a form of closed circuit grinding ...

vrm roller raw mill maintenace customer case. Vertical roller mill for cement raw minerals limestone, . Mls3726 Vrm How Coal Mill Is Operate | Crusher Mills, Cone ...

What Is The Procedure To Opperate A Ball Mill Of Cement . What Is The Procedure To Opperate A Ball Mill Of Cement. what is the procedure to operate a mill of cement .

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

3 1. Introduction 2. Types of cement mills in use today 3. Factors affecting ball mill performance 4. Ball mill improvements case examples 5.

Chaeng Vertical Roller Mill has simple process, compact structure, product fineness of 80μmR 3%, with steady and average product fineness. Application : Cement Plant ...

OK™ cement mill. 2 ... the OK™ mill is the premier roller mill for finish grinding of portland cement, ... if the mill is to operate for a long time with one spe

The cement mill on a cement plant are usually sized for a clinker consumption considerably greater than the output of the plant''s kilns. This is for two reasons:

Ball Mills How Coal Mill Is Operate. how to operate ball mill ... Coal Mill in Cement . Coal Ball Mill Application . to operate, safe to use, .

Full TextRS Publication. Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant. Sanjeev T. Patil. Departmentschemes to reduce power consumption in ...

CCR Operator vacancy in Damascus, Syria with Al Badia Cement. Search for more CCR Operator jobs in Damascus, ... operate and optimize the cement mill.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

Irish Cement Limited, ... Did not operate during these months ... Item Cement Mill 1 Cement Mill 2 Cement Mill 3 Cement Mill 4 K3 Grate Cooler K2 Grate Cooler Coal ...

CEMENT (Data in thousand ... Price, average mill value, ... Most multikiln plants continued to operate only one kiln in 2012. One idle plant was formally closed in ...

Home>Crusher and Mill >how to operate vertical mills in cement plant. how to operate vertical mills in cement plant. ... Cement Mill Process Manufacturers,cement ...

Nov 29, 2016· Video embedded· DETALS ABOUT CEMENT RAW MILL OPERATION : ... new cement plants are designed to operate on the dry process principle.

vertical mill,cement separator – Operate ... ... cement mill seperator principle of operation coal processing . find the right and the top cement mill seperator ...

How to Grind Cement eHow. Grinding cement or concrete is a dirty and difficult task. By following a set of steps with the right equipment, you can grind cement to be ...

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder making production line including cement, silicate...

system for the cement mill to reduce operational ... IRevival of the GMD in cement Mr P Subba Raju, MD Lalitha Cement, ... that operate with a rectifier and ...

WhatsApp)

WhatsApp)